PoSAddive - Powder Sheet Additive Manufacturing

Dr. Rocco Lupoi

lupoir@tcd.ie

+353 1896 1729

William Abbott

abbottw@tcd.ie

Wenyou Zhang

zhangw7@tcd.ie

Asli Coban

cobana@tcd.ie

Moyin Otubela

otubelam@tcd.ie

Consortium Members

Description

Additive manufacturing (AM) is experiencing increasingly wider adoption by automotive, aerospace, and medical industries because it unlocks new design freedoms. Metal AM methods typically use powder or wire as feedstock. Powder can either be pre-placed (with the common benchmark of Powder Bed Fusion, PBF) or blown towards the processing zone (Directed Energy Deposition, DED). Loose powder, however, shows several disadvantages:

1) Long clean-up times and labour intensive between prints

2) It is uneconomic and impractical to switch powder materials, thus not suitable for printing of functionally graded multi-material components

3) High Health & Safety requirements caused by storage of loose powders and human contact

4) High material consumption due to high amount of powder needs for supportive structure

5) High adoption cost of AM system

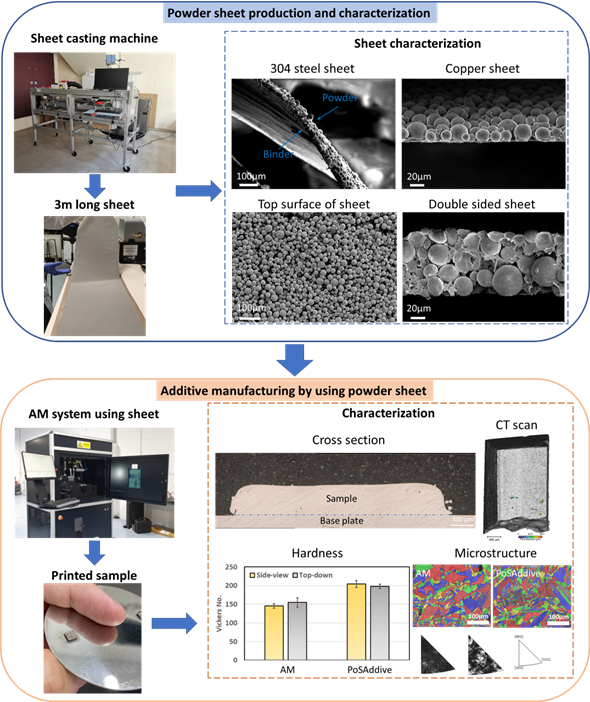

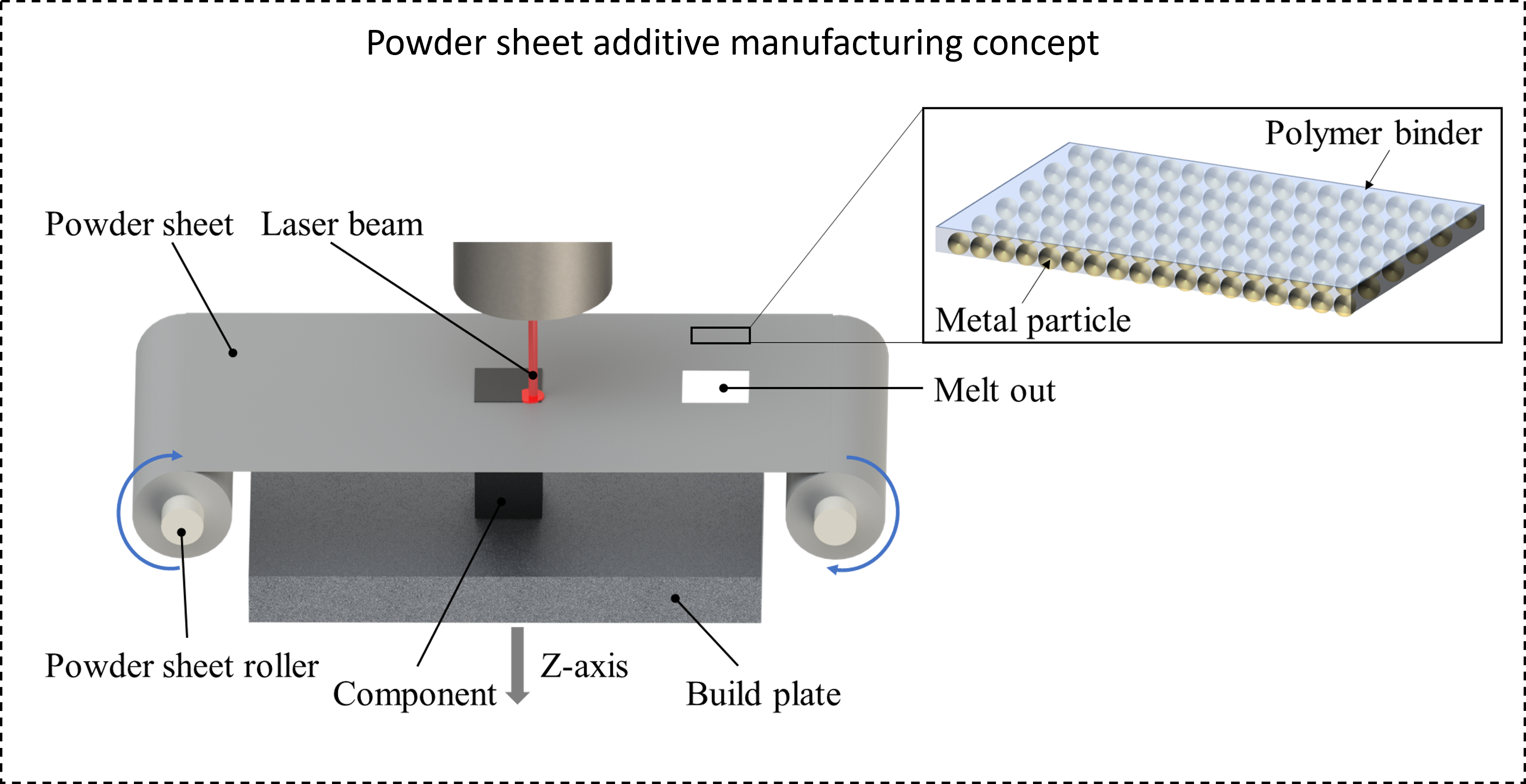

PosAddive will develop and then upscale a novel disruptive metal AM technology using flexible metal powder sheets, on which the powder material is attached with a newly developed binder technology to be locally transferred by a laser beam to form a new structure layer-by-layer, overcoming the problem of having loose powder in production. The unique features are the flexible variation of multi-material print by shifting the powder sheets, no machine contaminations, reduced health risks for humans, no restrictions on powder flowability and minimizing waste powder production due to easy powder sheet recycling. Those cost and technical advantages are expected to lead to a rapid acceptance by industry.