Supersonic-Assisted Laser Ablation

Dr. Rocco Lupoi

Prof. James Lunney

Dr. Stephen Davitt

Description

This project is about the development of a new coating process for thin films, based upon pulsed laser deposition (PLD), but with the potential to fully overcome low deposition rates and the practical disadvantages of vacuum processing. This is achieved through combining high repetition rate (HRR) laser ablation with the novel technique of Supersonic Assisted Laser Ablation (SALA) developed within Trinity College Dublin.

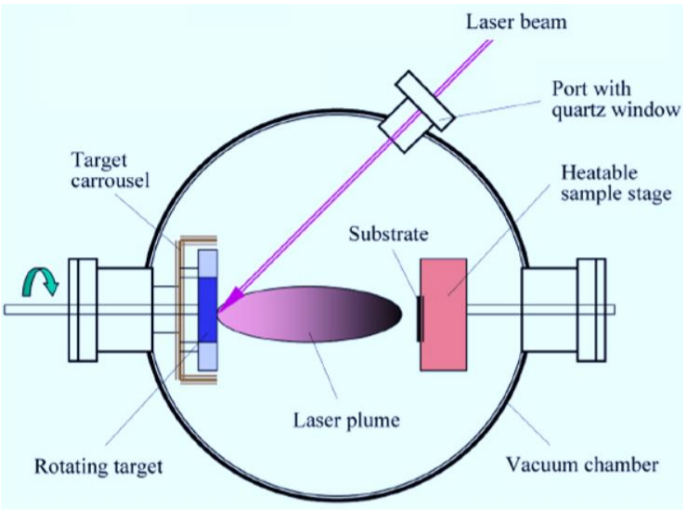

PLD is, in theory, a simple process that has been widely used over recent decades for making a wide variety of thin film materials for research. In a pulsed laser is used to vaporise a small amount of a target in a vacuum, or low-pressure gas, leading to an expanding vapour plume which is condensed on a suitable substrate, as can be seen in Figure 1. Despite this apparent simplicity, there are many process parameters which can affect the nature of the deposit. Even with optimal parameters, standard PLD deposits are typically limited to a few cm2 with deposition times ranging up to several hours, this strongly inhibiting the industrial application of PLD.

HHR laser ablation has been facilitated by the rapid advances in the development of HRR fibre lasers delivering pulses within kHz to GHz with an average power of 100W or more. When these laser beams are focussed to a tight spot diameter they produce very efficient ablation which can be used to greatly increase deposition rates. In addition to this, by performing the technique within atmospheric conditions eliminates the need for a vacuum chamber, making PLD more suitable for industrial applications. However due to increased confinement of the vapour plume at atmospheric pressure, the target and substrate separation must be very small <1.5mm.

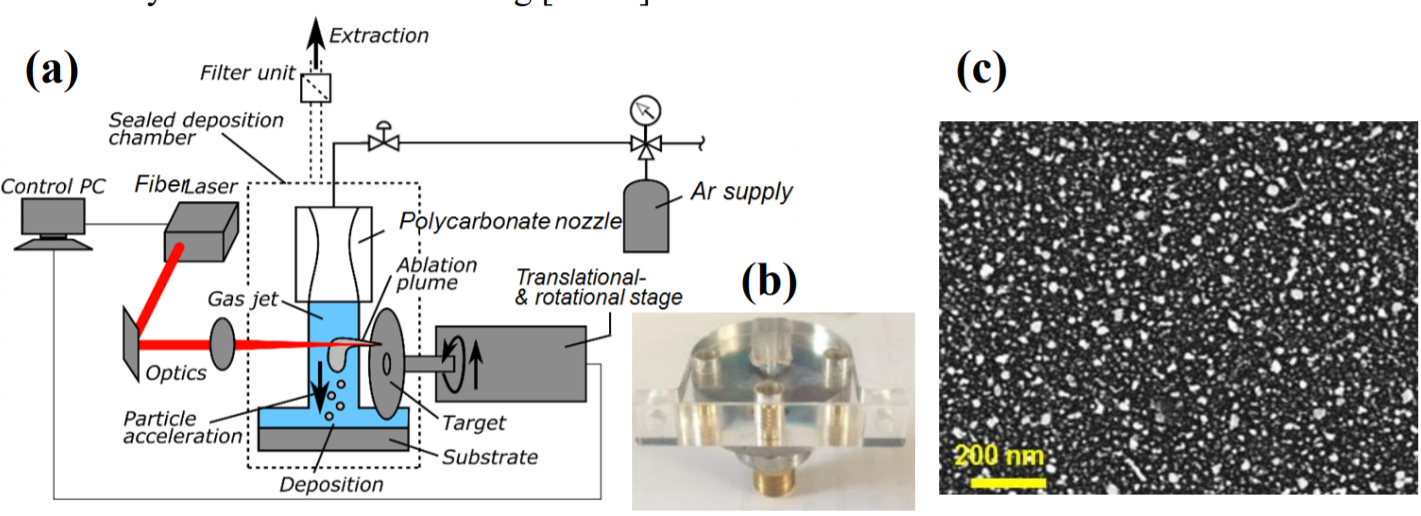

(a) Supersonic Assisted Laser Ablation (SALA) experimental setup; (b) A picture of the supersonic nozzle assembly; (c) SEM surface image of a preliminary Ag coating sample produced with SALA in Trinity College Dublin.

This is where the novel SALA technique has an opportunity to be a game changer. In this technique a supersonic gas jet is used to transport the laser ablation plume over several cm to a substrate where it is deposited. Figure 2 shows a diagram of the experimental setup, alongside and sample silver coating and supersonic arrangement.

The project aims to further develop this novel SALA technique along with combining HHR laser ablation to explore the technological potential of HRR-SALA as an industrial technique for thin film coatings.