The Development of Cold Spray towards the Next Generation of Additive Manufacturing

Project Coordinator

Dr. Rocco Lupoi

Email: [javascript protected email address]

Tel: +353 1 896 1729

Dr. Barry Aldwell

Mr. Richard Jenkins

European Space Agency (ESA)

Project Description

Cold Spray (CS) is an innovative coating manufacturing process, which allows for the formation of material layers in a solid-state (free of melting) manner.

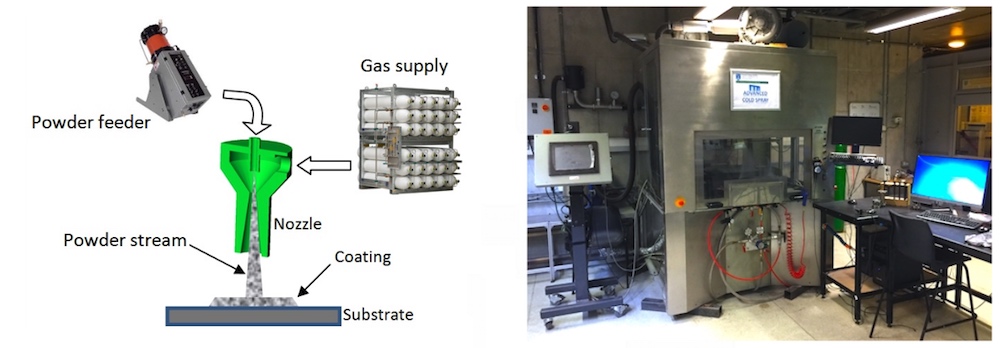

Cold Spray Methodology (left) and the STAM Cold Spray Chamber (right)

In this method, the feedstock material (in the form of powder) is injected at the inlet of a converging-diverging supersonic nozzle. The nozzle is fed with high pressure gas (nitrogen or helium), which expands through the internal channel and reaches supersonic speed at the exit (above 1000m/s). Particles are dragged by the fast jet, and upon impact against a substrate material they plastically deform and stay bonded.

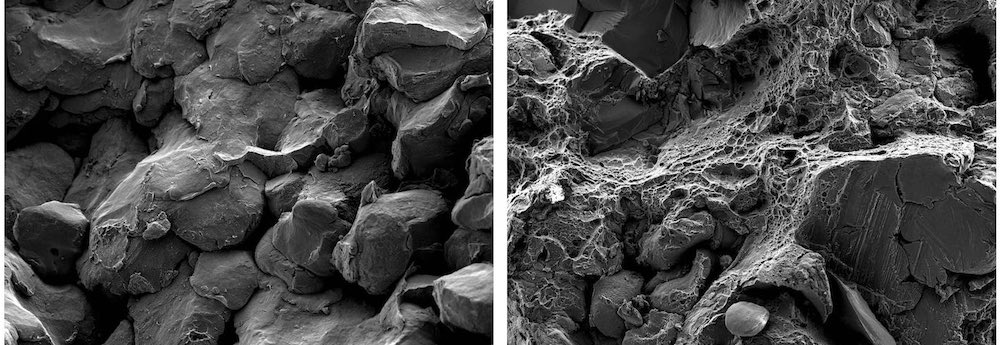

SEM image of Fracture Surfaces of Cold Sprayed Aluminium 6061

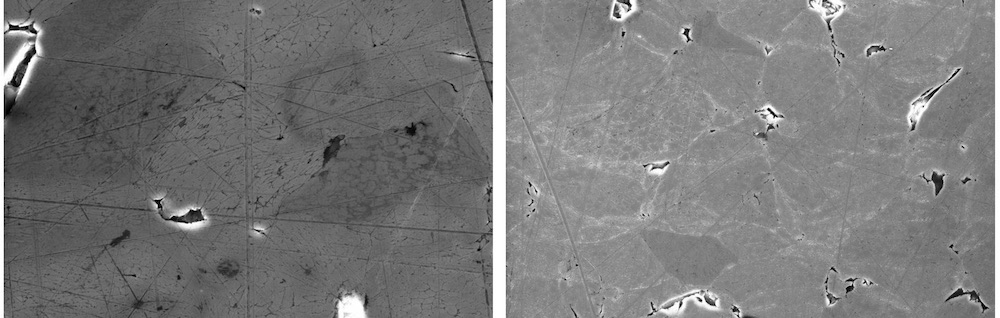

SEM image of Particle and Grain Deformation of Etched Cold Sprayed Aluminium 6061

The density of the coating can be very high, combined with astonishing build rates to approach 250g/min. Also, the solid-state nature of the process allows for the preservation of feedstock properties/micro-structure and the elimination of Heat Affected Zones (HAZ).

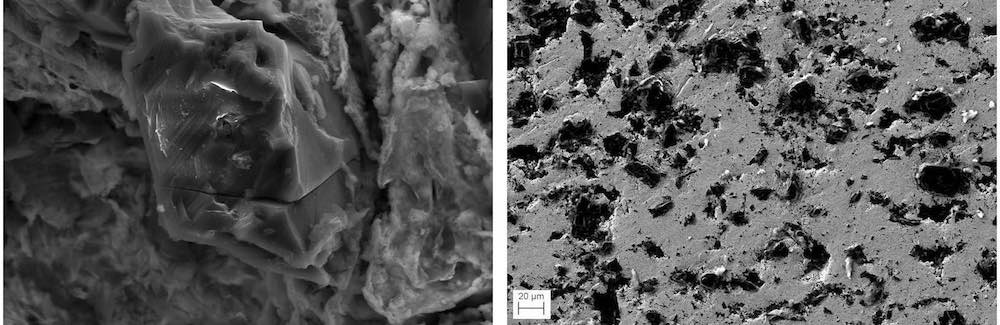

SEM images of a Metal Matrix Composite Manufactured Using Cold Spray

Typical applications relate to wear resistance, corrosion protection and change of surface properties. Due to the bonding mechanism, not metallurgically compatible combinations are possible such as for the deposition of metals onto polymers and composites for aerospace, automotive and bioengineering applications.

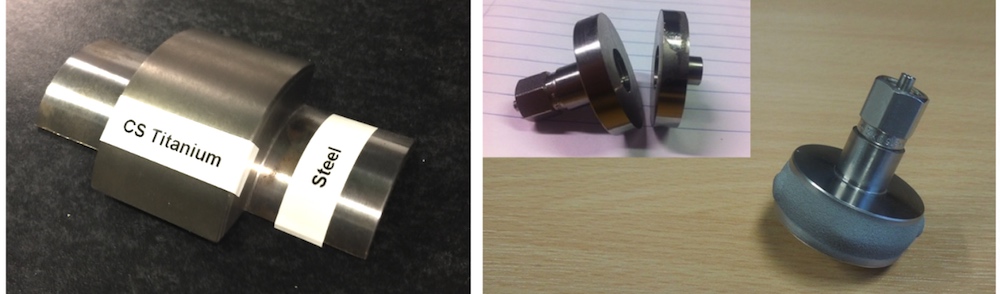

A Metal Matrix Composite Manufactured Using Cold Spray (left) and Aluminium Cold Sprayed onto PEEK (right)

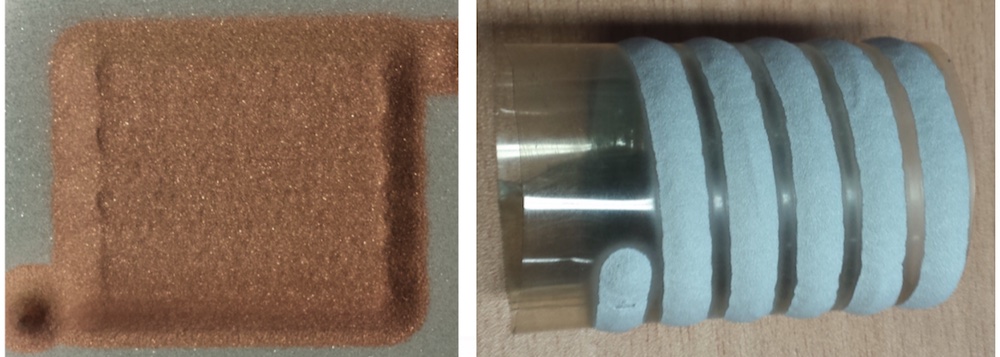

Titanium Cold Sprayed Onto Steel (left) and Components Bonded Together Using Cold Spray (right)

This project aims at developing a unique CS laboratory facility, the first one in Ireland. The programme has raised major interest from the industrial community, with a number of partners who have already contributed to its development.

Media Coverage

- The Irish Times: Research at Trinity to blaze a trail into 3D printing of metal components

- TCD.ie: Engineers to Fine-Tune 'Cold Spray' - the Next-Gen 3D-Printing Tech for Spacemen

- The Engineers Journal: European Space Agency funds TCD engineers' Cold Spray 3D printing

- IMechE: European Space Agency Funds 3D Printing Research

- Siliconrepublic.com: TCD team leading €500,000 ESA project to create future space tech

- 3DPrint.com: Dublin's Trinity College Receives Funding from ESA to Develop Cold Spray 3D Printing Technology

- Phys.org: Engineers to fine-tune 'cold spray,' a next-gen 3D-printing technology for astronauts

- 3D Printing Progress: Next-gen 3D printing tech for spacemen

- Engineering.com: Engineers to Fine-Tune 'Cold Spray' a Next-Gen 3D-Printing Technology for Astronauts

- AZoM.com: Trinity Engineers Lead ESA Project to Fine-Tune 'Cold Spray' 3D Printing Technology

- Imprimalia3d.com (in Spanish): Proyecto de ESA sobre el 'spray frío' y la nueva generación de la impresión 3D

- Factor-tech.com: Cold Spray 3D Printing Technique to Enable Quick Metal Printing in Space