News and Events

- Matteo Solazzo (supervisor Professor Michael Monaghan), TCBE PhD student wins 2nd place in the paper awards of the 22nd Sir Bernard Crossland Symposium and Postgraduate Workshop

- Professor Ciaran Simms appeared on Monday night’s Now You See Me on RTE to talk about cycling collisions

- Prof. Daniel Kelly won the ‘One to Watch’ Award in recognition of his bio-engineering achievements at the Trinity Innovation Awards 2019

- Bruce Murphy wins awarded the Campus Company Founders at the Trinity Innovation Awards 2019

- “It would have been a very good design process if they were designing a washing machine,” says Trinity College Dublin engineering professor David Taylor"

- Robert Gaul TCBE PhD student wins American Society of Mechanical Engineers award

- Irish Times Innovation and Technology Podcast featuring an interview with Danny Kelly TCBE Director and PI of Amber, discussing a pioneering project aimed at developing 3D-printed biological implants to treat people affected by degenerative diseases such as osteoarthritis

- New 3D printing project aims to bring relief to arthritis sufferers

- Trinity Centre for Bioengineering co-hosting the 8th World Congress of Biomechanics 8-12 July, Dublin, Ireland

- Bioengineers identify safer ways to make rugby tackle

- TCBE researcher win Engineers Ireland Biomedical Medal

- TCBE Newsletter Spring 2016

- TCBE Newsletter Summer 2012

- MSc Bioengineering awarded Best Postgraduate Course of the Year 2012 in Engineering

- Honorary Fellowship

- TCBE Newsletter Spring 2012

- TCBE researchers help to protect clear vision in patients with a particular eye disorder

- TCBE collaboration with Moorings Mediquip results in new product to help children with disabilities to learn to walk

- European Commission Awards €4.8 Million to ICT Project that will help Older People and those with Neurological Disorders

- Contactless sensors detect developing pressure ulcers

- TCBE Newsletter 2011

- New Laboratories and a New PhD Programme in BioEngineering

- TCD Bioengineer awarded prestigious European Research Council grant to develop new mesenchymal stem cell based therapies for articular cartilage repair

- Bone Grafting August 2010

- Engineering, Medical and Biomedical Students Design Next Generation Medical Devices at ESEM Summer School at TCD July 2010

- Basic Engineering for Medics and Biologists June 2010

Read the latest news on TCBE people and activities, papers and publications.

MSc Bioengineering awarded Best Postgraduate Course of the Year 2012 in Engineering

Congratulations to the M.Sc. in Neuroscience won the 'Best Postgraduate Course of the Year 2012 in Science' award.

Winner of the 2012 postgradireland Postgraduate Course of the Year award for engineering - M.Sc. in Bioengineering, Trinity College Dublin, University of Limerick, University College Dublin, Royal College of Surgeons in Ireland. Left-to-right: Dr. Kevin O’Kelly, June O’Reilly (both Trinity College Dublin); Eucharia Meehan, Head of Research Programmes and Capital Investment, HEA; Gavan O’Brien, gradirelandPhoto: Nikki Browne

All the winners of the gradireland Graduate Recruitment awards and postgradireland Course of the Year awards 2012

Trinity alumnus and Professor of Anatomy in the Royal College of Surgeons in Ireland and in the Royal Hibernian Academy, Professor Lee has strong connections with Trinity having been Visiting Professor of Biomechanics and Tissue Engineering since 2003.

The announcement was made by the Provost of Trinity, Dr Patrick Prendergast, surrounded by members of the Board of the College in full academic gowns and hoods on the steps of the Public Theatre. Research achievement or scholarship of a high order is the primary qualification for Fellowship, along with evidence of the candidate’s contribution to the academic life of the College and an effective record of teaching.

Professor Clive Lee is photographed here with his wife Hannah, daughter Sophie and the Provost Dr. Patrick Prendergast after receiving Honorary Fellowship of Trinity College Dublin. He is the first PI of the Centre for Bioengineering to receive Honorary Fellowship of College, and we congratulate him on this achievement.

TCBE researchers help to protect clear vision in patients with a particular eye disorder

TCBE Award winners at Bioengineering in Ireland conference 2012

TCBE collaboration with Moorings Mediquip results in new product to help children with disabilities to learn to walk

Trinity Centre for Bioengineering delivers excellence in the translation of innovative solutions into medical devices and practical applications that enhance patient care, thus enriching and facilitating the development of the medical device industry in Ireland. Collaboration with the Trinity Centre for Bioengineering facilitated the development of a design and manufacturing capability within Moorings Mediquip in Ballymena that led to a new product, the Buddy Roamer, a walking aid to help children with physical mobility challenges. This was featured in the Irish Times on Monday 9th January 2012.

Personalised Virtual Reality Scenarios for Groups at Risk of Social Exclusion A project aimed at improving the quality of life for disadvantaged groups including older people and those with neurological disorders has been awarded €4.8 million by the European Commission Seventh Framework Programme. The international project, named ‘VERVE’, is coordinated by Trinity College Dublin and includes collaborative partners in healthcare and academia in France, UK, Italy, Spain and Germany. The project will develop tools to support the treatment of people who are at risk of social exclusion due to fear and apathy associated with ageing or a neurological disorder. The VERVE consortium will apply leading edge research to simulate personalised and populated virtual reality environments, 3D web graphics, and ‘serious’ games as a means to addressing some of the challenges faced by the target groups. A variety of clinical, laboratory and industry partners will help design the therapeutic tools and games, and evaluate their usefulness with participants. The project team will also work with those at risk of social exclusion, as well as their carers, families, health professionals and relevant support organisations, to solicit ideas and feedback and to promote the project’s aims and achievements. In addition to coordinating the project, Trinity’s Graphics Visualisation and Vision (GV2) group, led by Prof Carol O’Sullivan, will build on their SFI-funded Metropolis project to create novel solutions for doctors to create compelling scenarios depicting virtual humans, groups and crowds in a personalised virtual city environment. The Trinity College Institute of Neuroscience (TCIN) researchers, Prof Fiona Newell and Prof Richard Reilly, will bring their experience on the assessment and treatment of falls and frailty, and gait disturbances in Parkinson’s disease, together with senior clinical collaborators in the Falls and Blackout Unit in St James’s Hospital and in the Dublin Neurological Institute at The Mater Misericordiae University Hospital. The VERVE consortium partners are Trinity College Dublin (Ireland), Chu de Nice: The Central University Hospital of Nice; INRIA: Institut National de Recherche en Informatique et Automatique, and CNRS: Centre National de la Recherce Scientifique (France), Testaluna (Italy), Kainos Software (UK), Universidad de Zaragoza (Spain) and DFKI: Deutsches Forschungszentrum für Künstliche Intelligenz (Germany). Medical-sensing technology could alert clinicians to the development of pressure ulcers in immobile patients before they form. The contactless system, developed by Irish researchers, focuses on detecting tissue blood flow — or perfusion — which when restricted can lead to ulcers. Currently there are methods to detect pressure at the interface between skin and supporting surfaces, but this only provides a proxy for perfusion. Perfusion itself can be measured using bulky apparatus such as ultrasound, plethysmography or electromagnetic flowmetry, but these too have drawbacks — as project collaborator Dr Sonja Hermann of Trinity College Dublin explained. Following the Higher Education Authority’s (HEA) announcement of PRTLI-Cycle5, the Trinity Biomedical Sciences Development is to receive significant funding of €55 million. The 29,000-m2 TCD Biosciences Development will provide the Trinity Centre for Bioengineering with additional research facilities in this new state-of-the art Development including laboratories for Regenerative Medicine, Cardiovascular, Biomaterials, Neural Engineering along with an impact test facility. The PRTLI program is also funding the Trinity Engineering PhD programme proposal for €2.8 million. This funding will provide the infrastructure for high quality bioengineering PhD graduate education that will produce the critical mass of talented and capable bioengineers required to underpin the design and development of medical devices that will drive economic growth and sustainability. The funding will provide an initial cohort of bioengineering researchers with advanced education in Bioengineering and Medical Device Technologies, and is in collaboration with University College Dublin. The programme will also provide the additional skills to enable the students to recognise how their research can lead to the innovation and creative design process fundamental to a sustainable medical device sector. This is a new departure from existing practice and provides a focused, coordinated education geared towards enabling the student’s creativity and research skills whilst enhancing the impact of their research through technology transfer and potential for “start-ups”. The new program will build on the Trinity Centre for Bioengineering’s existing educational programs: undergraduate modules, International Summer School, MSc and Erasmus Mundus MSc postgraduates courses. The ERC is the newest, pioneering component of the EU's Seventh Research Framework Programme. Set up in 2007 by the European Commission, the ERC aims to stimulate scientific excellence in Europe by supporting the very best, creative researchers of any nationality working, or moving to work, in Europe. The focus Dr. Kelly’s lab is to understand how environmental factors regulate the phenotype of adult stem cells, and the subsequent functional properties of the tissues they produce. He is specifically interested in utilizing such stem cells in the repair of damaged and diseased articular cartilage. As articular cartilage has a limited reparative capacity lesions often progress to arthritis. This has motivated the development of cell based therapies for the repair of cartilage defects. Unfortunately such therapies are limited in a number of ways. Firstly, the repair is often temporary, and secondly, widespread adaptation into the clinical setting is impeded by practical issues such as the high cost and time required for such procedures. Dr. Kelly’s ERC project aims to develop novel solutions to both of these problems. The first theme of the project will determine whether MSCs freshly isolated from fatty and synovial tissue in an injured joint, and then embedded in a hydrogel containing microbead-encapsulated growth factors, can used to engineer functional cartilage tissue. The project builds on earlier findings from Dr. Kelly’s lab that functional cartilaginous tissue can be engineered using MSCs isolated from within the intrapatellar fat pad of the knee. The ultimate aim is to develop a cell based therapy that from MSC isolation to construct implantation could be undertaken within hours in the clinical setting. You probably don’t think much about your skeleton – until something goes wrong. Bone grafting is currently a difficult process, with many associated problems. RCSI have developed a material which could change all this.

Disease and injury can damage joints and bones, sometimes to the point where you need surgery to replace or repair them and, no matter how you look at it, that kind of surgery is an invasive business. July, 22nd, 2010 – Thirty engineering, medical and biomedical engineering undergraduate students from across Europe are designing next generation medical devices at the Trinity Centre for BioEngineering at Trinity College Dublin as part of the European Society for Engineering and Medicine (ESEM) Summer School this week (July 11th -23rd). This is the second year for this unique European summer school, organised in collaboration between eight leading universities in biomedical engineering and medicine, apart from Trinity College Dublin these are the University of Groningen (NL), Ghent University (B), Brno University of Technology (CZ), Czech Technical University in Prague(CZ), RWTH University Aachen (D), University of Applied Sciences Regensburg (D) and the Royal College of Surgeons in Ireland (IRL). TCBE NEWS is a monthly communications initiative with all news and updates of activities and research within the Trinity Centre for Bioengineering. If you would like to receive the latest edition of TCBE News, email, tcbe@tcd.ie and you will be added to our subscription list. Recent editions Developments in bioengineering and medical technology have led to spectacular progress in clinical medicine. As a result, increased numbers of courses are available in the area of bioengineering and clinical technology. These often include modules dealing with basic biological and medical sciences, aimed at those taking up these studies, who have a background in engineering.  The Buddy Roamer is being manufactured by Co Antrim based SME Moorings Mediquip, which was given support through a project called InterTradeIreland Fusion. The scheme buddied-up the family business with Dr Ciaran Simms, a principal investigator in the Centre for Bioengineering at Trinity College, and an expert on biomechanics and a design graduate and the result is that they are now exporting the Buddy Roamer.

The Buddy Roamer is being manufactured by Co Antrim based SME Moorings Mediquip, which was given support through a project called InterTradeIreland Fusion. The scheme buddied-up the family business with Dr Ciaran Simms, a principal investigator in the Centre for Bioengineering at Trinity College, and an expert on biomechanics and a design graduate and the result is that they are now exporting the Buddy Roamer.

European Commission Awards €4.8 Million to ICT Project that will help Older People and those with Neurological Disorders

VERVE’s efforts will focus on three situations, each targeting a different group of participants: fear of falling and Parkinson’s disease; apathy related to cognitive decline and behavioural disturbances, in particular due to Alzheimer’s Disease; and other emotional disturbances linked to anxiety. Although focusing on these areas initially, it is expected that the results of the research will be applicable to a much wider range of potentially disadvantaged individuals.

Commenting on the significance and aims of the project, Trinity College Dublin’s Professor of Visual Computing and VERVE project coordinator, Carol O’Sullivan says: “The end goal of the novel ICT technologies being developed in VERVE is to increase user ability, allowing older people and those with neurological disorders to overcome their fear, apathy or phobia and thus carry out daily life activities in a fulfilling and dignified manner. The key to our success will be the fact that the clinical intermediary users will be actively participating during the development of the ICT tools and platforms, and will thus guarantee that the end result will be usable and accepted by the end-users."Contactless sensors detect developing pressure ulcers

‘You can only measure by lifting the limb or the part you’re interested in off the surface, so there’s no really direct measurement of what’s going on when people are lying or sitting down. ‘Also, by using these methods — for example, with the ultrasound head — you actually apply pressure onto the skin and by doing so you’re changing the environment you’re trying to measure.’

The team’s solution was to use a commercially available thin-film ferroelectret sensor — a material that shows similar behaviour to piezoceramics by generating a current upon mechanic stress. They were able to adapt these sensors to capture a ballistocardiogram (BCG) profile, which describes the recoil acceleration in blood vessels from flow and thus tissue perfusion. Crucially, the sensors can be placed underneath mattresses, wheelchairs or any supporting surface, allowing true in situ monitoring. The device can then be coupled to a laptop where the data is fed through bespoke algorithms and interpreted by a clinician.

Hermann said the information could potentially be used in conjunction with the pressure-release mattresses that some hospitals now use. These are essentially air-filled beds that shift pressure in cycles so one body part is never under pressure for too long. ‘It works okay, but they [nurses] don’t really know when to initiate these cycles and how to actually manipulate them according to the patients’ data, there might only be two or three settings. ’It’s a very rough estimate that has to fit all people, and every patient has a different risk of pressure ulcers in different areas of the body.’

In the future though, the data from the BCG sensors could feed into an entirely automated pressure-relief system, in a ‘closed-loop’ fashion. Hermann and colleagues are now performing clinical trials in order to gain a better understanding of how different illnesses effect perfusion, with funding from the Irish Research Council for Science, Engineering and Technology (IRCSET) and Center for Excellence in Universal Design. MSc Bioengineering class of 2009-2010 Commencements

New Laboratories and a New PhD Programme in BioEngineering

TCD Bioengineer awarded prestigious European Research Council grant to develop new mesenchymal stem cell based therapies for articular cartilage repair

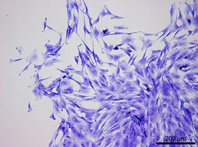

Dr. Daniel Kelly, a lecturer in TCD’s School of Engineering, and a Principal Investigator at the Trinity Centre for Bioengineering, has been awarded a major European Research Council (ERC) Starter Grant of €1.5 million. The project aims to use Mesenchymal Stem Cells (MSCs) that can be isolated from within damaged or diseased joints such as the knee to regenerate articular cartilage.

Dr. Daniel Kelly, a lecturer in TCD’s School of Engineering, and a Principal Investigator at the Trinity Centre for Bioengineering, has been awarded a major European Research Council (ERC) Starter Grant of €1.5 million. The project aims to use Mesenchymal Stem Cells (MSCs) that can be isolated from within damaged or diseased joints such as the knee to regenerate articular cartilage. The second theme of the project will explore an alternative therapy for cartilage defect repair. Specifically, the objective is to tissue engineer in vitro a functional tissue with a zonal structure mimicking that of normal articular cartilage using MSCs. It is hypothesised that such a zonal structure can be generated by controlling the oxygen tension and mechanical environment within the developing tissue. Dr. Kelly’s lab has already demonstrated that both of these environmental cues are key regulators of stem cell differentiation along the chondrogenic lineage, and also influence the functional properties of cartilaginous tissues generated by the cells. By re-engineering fully functional cartilaginous grafts in vitro, it is hoped that cell-based therapies can be expanded to treat larger defects and osteoarthritic joints.

The second theme of the project will explore an alternative therapy for cartilage defect repair. Specifically, the objective is to tissue engineer in vitro a functional tissue with a zonal structure mimicking that of normal articular cartilage using MSCs. It is hypothesised that such a zonal structure can be generated by controlling the oxygen tension and mechanical environment within the developing tissue. Dr. Kelly’s lab has already demonstrated that both of these environmental cues are key regulators of stem cell differentiation along the chondrogenic lineage, and also influence the functional properties of cartilaginous tissues generated by the cells. By re-engineering fully functional cartilaginous grafts in vitro, it is hoped that cell-based therapies can be expanded to treat larger defects and osteoarthritic joints. back to top

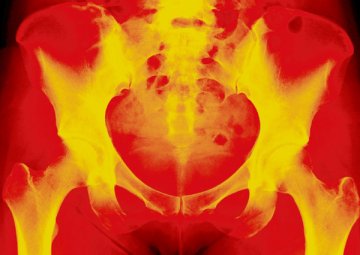

Bone Grafting

Bone Grafting

But research at the Royal College of Surgeons in Ireland (RCSI) has come up with a bone graft substitute material to aid the healing and regeneration process.

The components and porous design of the material mean that, once implanted, it encourages the patient’s own bone to remodel at the injury site, and it supports new growth like a scaffold. The implanted material – known as HydroxyColl – degrades over time, leaving the new bone in place.

HydroxyColl is made of hydroxyapatite and collagen, substances that occur naturally in bone. It takes advantage of the bone tissue’s inherent ability to regrow, explains Dr John Gleeson, project and business development manager at RCSI’s Department of Anatomy.

“Bone is a very active material and remodels frequently,” he says. “It has an amazing ability to repair itself naturally once you don’t have too big a defect or site of damage.”

However, the current approach of surgically grafting actual bone tissue onto a site of injury can create problems.

“Currently the clinical gold standard is autografting whereby, if you need to augment the repair process, you would take a piece of bone from another site in the patient’s own body and reimplant it into the site that is damaged,” says Gleeson.

But that means another surgery site for the patient and, if there’s an underlying problem with the person’s bones, such as osteoporosis, the grafted bone may suffer from it too.

Another solution has been “allografting”, using bone donated from others, but the patient’s immune system could reject the donor graft, explains Gleeson. He says the practice of processing donated bone material can also have an impact on how the graft performs.

“Bone is harvested from donor patients from a number of sites worldwide. They would usually be stored in bone banks, or commercial businesses store and process these to reduce the risk of transmission of infectious disease,” he says. “But the process can remove cellular material that could promote the regenerative process once in the body.”

The alternative is a bone graft substitute. Some commercial products use materials coated with drugs to encourage bone tissue to grow, but Prof Fergal O’Brien’s research at RCSI has been developing HydroxyColl as a ‘bioactive’ material where the secret lies in the properties and design of the material itself, explains Gleeson.

“It’s optimised and designed to play a significant role in guiding a regenerative process as well as supporting it,” he says, explaining how the material can offer a scaffold to direct new growth.

“Cells can be directed and controlled to a certain extent by a number of different characteristics. The material they sit on has quite an influence on what they do, what they produce and what they might turn into.”

The porosity of the material also means that blood vessels can grow through the site and deliver nutrients and oxygen to the regenerating tissue, adds Gleeson.

“Our product is a highly porous material, it’s 99 per cent air, so there is lot of space for cells to get in and for them to grow networks, for fluids to perfuse,” he says. “It allows them to grow dynamically.”

Then, as the healing progresses, the bone substitute dissolves away.

“It’s highly biodegradable – we are able to match the regeneration of new tissue with the biodegradation of our scaffold,” says Gleeson. “So our material is made of the building blocks the cells are going to work with, and the cells are capable of remodelling what we put in there and then getting rid of it when they no longer need it.”

Pre-clinical trials have shown ‘phenomenal’ results, according to Gleeson. “We saw evidence, not only of healing, but that the bone is being actively remodelled or reshaped to return to the normal anatomy of the tissue itself,” he says.

Clinical trials are due to start this year through RCSI’s Cenre for Innovation in Surgical Technology. Gleeson reckons that in the long-term, HydroxyColl will be an “excellent material for small-to-medium sized bone grafts”. He notes that for large defects in bone or for older patients (who may have less of an inherent capacity to regenerate bone tissue) the scaffolds might be treated with additional growth factors before being used.

The team is also looking at the possibility of applying the material to dental practice.

“We have in the works a parallel study which is looking at using the material for dental reconstruction to improve the bedrock of the jaw,” says Gleeson. “So you have someone who is losing their teeth as they get older, their jawbone thins and you could maybe use these materials to improve the base where a dentist could implant a tooth.”

The scaffold could also be used for growing bone material in the lab before implantation into a patient. Research is currently underway at RCSI into optimising that process.

HydroxyColl is one of the technologies being presented at Enterprise Ireland’s Big Ideas Technology Showcase at Croke Park in October

The Irish Times - Friday, August 27, 2010back to top

Engineering, Medical and Biomedical Students Design Next Generation Medical Devices at ESEM Summer School at TCD

Engineering, Medical and Biomedical Students Design Next Generation Medical Devices at ESEM Summer School at TCD

“Current healthcare challenges, such as the ageing of Europe 's population as well as big killers such as cardiovascular disease, require multidisciplinary approaches for diagnosis and treatment. The focus therefore of this unique summer school is to establish a platform of cooperation between medicine and engineering across Europe starting at an undergraduate level,“ explained Professor Richard Reilly, Director of the Trinity Centre of BioEngineering and organiser of the Summer School.

With different working cultures and educational backgrounds, the aim of the European Society for Engineering and Medicine Summer School at Trinity College has been to teach students how to work together efficiently by getting small groups to design new, novel medical devices targeting specific medical and clinical problems. These include the design of a cardiovascular monitoring system and a system to prevent bone loss, both for use in long-duration deep-space flights, as well as technologies to monitor the healthcare of the elderly and the design of artificial ventilation systems.

To have the educational basis to undertake this challenge, the students are taking courses delivered by 15 leading Professors of Biomedical Engineering and Medicine, who also join the students at Trinity College . The medical students are instructed in bioengineering methods (materials science, mathematics, biomechanics, signals and systems) necessary to successfully work in biomedical engineering while engineering students are instructed in anatomy and physiology at the Royal College of Surgeons in Ireland . Both groups of students are taught design methodologies for furthering their understanding and capability to understand, analyse and successfully conceptualise innovative medical device concepts using a multidisciplinary team approach. The students are also exposed to some of the ongoing multidisciplinary research in Trinity College, including demonstrations on Sports Physiology in the School of Medicine and also The Longitudinal Study on Ageing (TILDA), which is studying 8,000 people, aged 50 and over, charting their health, social and economic circumstances over a 10-year period.

“We want future biomedical engineers and clinicians to understand each other's discipline,” said Professor Bart Verkerke of the Department of Biomedical Engineering at the University Medical Center Groningen and ESEM President.

“The impact of this summer school has been to ignite enthusiasm and passion among undergraduate engineers and medical students for the challenges and opportunities in bioengineering,” continued Professor Richard Reilly, Director of the Trinity Centre of BioEngineering.

“There are currently over 11,000 medical technology companies in Europe , exporting €65 billion worth of products annually and employing 500,000 people. It is critical that we can demonstrate to these students that engineering innovation and creative design can meet the challenges in healthcare, continue the growth of medical device sector and the delivery of the best medical care possible,” concluded Professor Reilly.

Students participating in the summer school are learning in a unique environment which was reflected in their comments of the programme:

“I am learning the differences in culture between medics and engineers. And I am learning to follow the Methodological Design Method for generating ideas concerning a specific problem and to optimise the organisation of a multidisciplinary project team.”

“The ESEM summer school will give me the opportunity to improve my knowledge of engineering in medicine and healthcare, meet other students from different countries and discuss with them in a constructively critical atmosphere.”

“I am amazed by what can be done and the directions one can take with this specialisation. I also have gained an overall understanding of modelling and simulation.”

‘I gained a lot of knowledge from the medical environment provided through the ESEM Summer School and the participating professors. It helped me carry out our project and to understand other participants' projects as well. “

The outcome of the collaboration will lead to continued interaction of the students throughout their undergraduate and also postgraduate career through the network established by ESEM. The novel project outcomes will be published on the society's website (www.esem.org) to further disseminate to the medical device industry and wider community.

The 2011 ESEM Summer School is also scheduled to take place at Trinity College . There is considerable opportunity for the medical device sector to get involved in the Summer School and participate in the lectures and project assignments. Interested industries can contact ESEM.

Former students of 2009 Summer School have already decided to take their biomedical engineer career to the next level, by registering for the new Erasmus Mundus MSc in Biomedical Engineering. This funded postgraduate programme is also organised by the same consortium of European universities and is also focusing on preparing students for an international career in Biomedical Engineering.

For media queries contact, TCD Press Officer, Caoimhe Ní Lochlainn, tel: 8962310\ 087-9958014

Professor Richard Reilly and visiting experts at the ESEM Summer School are available for interview on request. back to top

TCBE News

back to top

Basic Engineering for Medics and Biologists

To date, relatively few participants from medicine have taken up courses in biomedical engineering, to the detriment of scientific exchange between engineers and medics. The European Society for Engineering and Medicine (ESEM) aims to bridge the gap between engineering and medicine and biology. It promotes cultural and scientific exchanges between the engineering and the medical/biological fields.

This primer consists of a series of First Step chapters in engineering and is principally presented for those with a medical or biology background who intend to start a MSc programme in biomedical engineering, and for medics or biologists who wish to better understand a particular technology. It will also serve as a reference for biomedical engineers.

Written by engineers and medics who are leaders in their field, it covers the basic engineering principles underpinningicall: biomechanics, bioelectronics, medical informatics, biomaterials, tissue engineering, bioimaging and rehabilitation engineering. It also includes cliny relevant examples.

To purchase click here http://www.iospress.nlback to top

back to top