Scientists unlock four-fold boost in performance of green energy catalyst

Posted on: 18 May 2017

A tiny amount of squeezing or stretching can produce a big boost in catalytic performance, according to a new collaborative study involving scientists from Trinity College Dublin, Stanford University, SLAC National Accelerator Laboratory, Lawrence Berkeley National Laboratory, and the University of Pennsylvania.

The discovery, published today in the leading journal Nature Communications, focuses on an industrial catalyst known as cerium oxide, or ceria, a spongy material commonly used in catalytic converters, self-cleaning ovens and various green-energy applications, such as fuel cells and solar water splitters.

Assistant Professor of Materials Science and Engineering at Stanford and a faculty scientist at SLAC, Will Chueh, was co-author. He said: “Ceria stores and releases oxygen as needed, like a sponge. We discovered that stretching and compressing ceria by a few percent dramatically increases its oxygen storage capacity. This finding overturns conventional wisdom about oxide materials and could lead to better catalysts.”

Catalytic converters

Ceria has long been used in catalytic converters to help remove air pollutants from vehicle exhaust systems. It essentially takes oxygen from poisonous nitrogen oxide to create harmless nitrogen gas. The ceria then releases stored oxygen and converts lethal carbon monoxide into benign carbon dioxide.

Studies have shown that squeezing and stretching ceria causes nanoscale changes that affect its ability to store oxygen. In particular, it has been suggested that stretching ceria would increase its capacity to store oxygen, whereas compressing it would decrease this capacity.

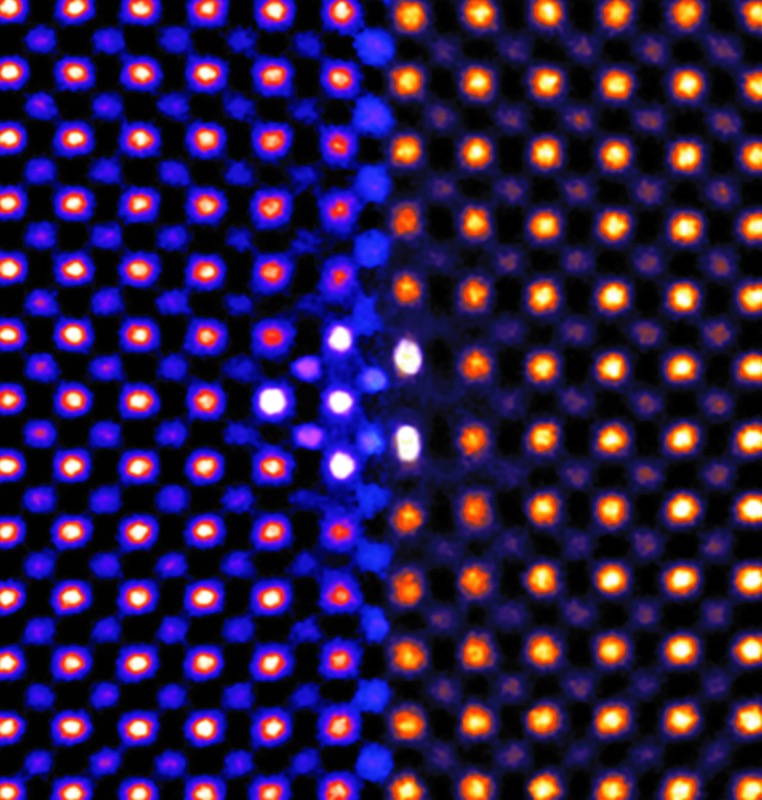

To test this prediction, the research team grew ultrathin films of ceria, each just a few nanometers thick, on top of substrates made of different materials. This process subjected the ceria to enormous stress equal to 10,000 times the Earth’s atmosphere, and caused the molecules of ceria to separate and squeeze together a distance of less than one nanometer.

Surprise results

Typically, materials like ceria relieve stress by forming defects in the film. But atomic-scale analysis revealed a surprise. Analysis of the position of individual atoms showed that the films of ceria remained stretched or compressed without forming any defects – allowing the stress to remain in full force.

To measure and rationalise the impact of stress under real-world operating conditions, the researchers then used the brilliant beams of X-ray light produced at Lawrence Berkeley National Laboratory’s Advanced Light Source along with supercomputers. The results were even more surprising.

Ussher Assistant Professor in the School of Chemistry at Trinity College Dublin, Max García Melchor, said: “Whether we stretched or compressed the ceria we found that the strained films showed a fourfold increase in oxygen capacity, which is pretty huge. There are a lot of potential applications for this in using catalysis to improve the efficiency of energy conversion and storage, including in green-energy technologies.”

“We hope that we may use this discovery to develop new clean fuels from carbon dioxide or water to power our cars and homes, for example.”

The journal article (DOI:10.1038/ncomms15360) can be read here.