Auto-CASM - Compressed Air Systems Metrics

Project Coordinator

Dr. Garret O'Donnell

Garret.ODonnell@tcd.ie

+353 1 896 1184

Dr. Sean Nolan

snolan1@tcd.ie

Description

Compressed air (CA) is used extensively in manufacturing to drive production lines and for material handling in manufacturing processes. Compressed air devices include blowers, nozzles, vacuum ejectors, linear actuators, air motors and machine tools. Within one automated machine the device count can be in the hundreds.

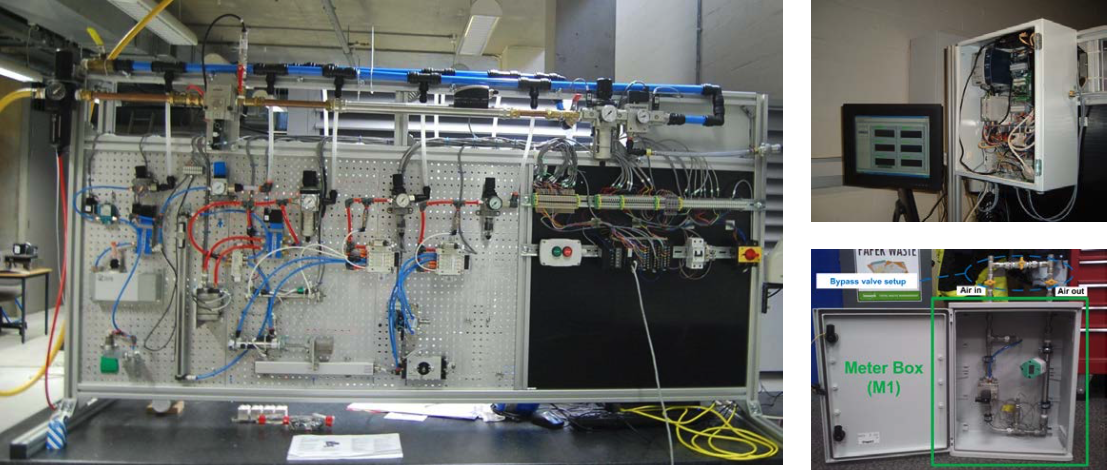

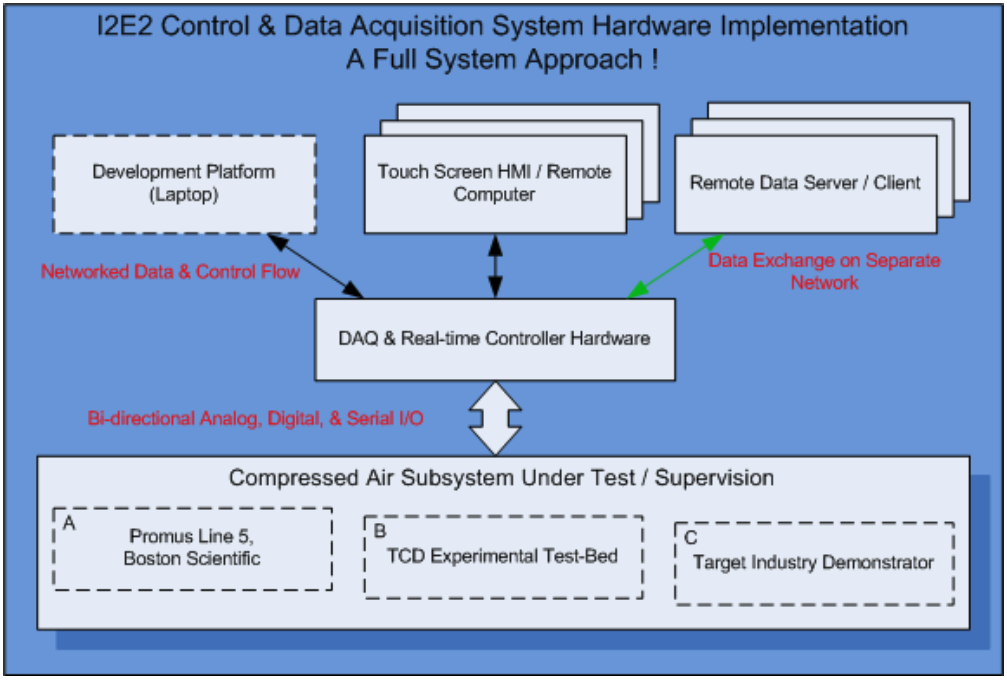

AutoCASM combines CA consumption monitoring, system health monitoring and fault diagnostics functionality within a single solution that is optimised for applications on point of use equipment and automated pneumatic machines. CA system monitoring solutions on the market do not provide fault/leak diagnostics capabilities.

Auto-CASM Approach

Auto-CASM is both a monitoring and supervisory system allows pneumatic machine designers and equipment operators to monitor and improve the energy efficiency of Compressed Air driven manufacturing processes. Key advantages of the system are:

- Mobile Data Acquisition & Logging of CA Metrics

- Monitoring & Control of automated CA sub-systems

- Online Fault Diagnostics of CA Systems

- Online & Offline Leak Diagnostic & Evaluation

- Software to improve visibility on machine/device air consumption

- Automated testing and test scheduling