Facilities & Services

The facilities at STAM enable our world class research in Additive Manufacturing, Machining and Joining, and Manufacturing Process Analytics.

These wide ranging capabilities, combined with our expertise and knowledge, allow us to offer services such as rapid prototyping, mechanical testing, imaging microscopy, rapid evaluation, and data logging and analysis.

Additive Manufacturing Facilities

3D Metal Printers

In Collaboration with AMBER STAM has access to the new AMBER AR-laboratory, and its high performance Additive Manufacturing technologies. The Realizer SLM 50 and ProX DMP 200 are high-performance, high-quality 3D printing alternative to traditional manufacturing processes, offering reduced waste, greater speeds for production, short set up times, very dense metal parts, and the ability to produce very complex assemblies as single parts.

They produce consistently high accuracy parts with exceptional surface finish and resolution, minimal waste of materials and the ability to produce parts not normally manufacturable using traditional methods with a shortened production time and increased part precision, using a broad choice of materials.

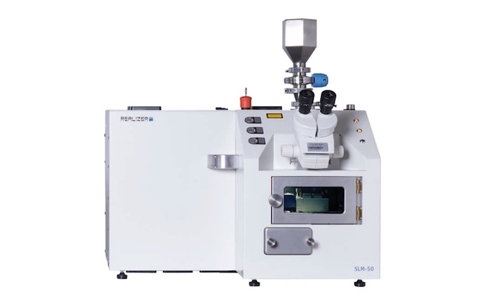

Realizer SLM 50

Specifications

| Technology | Selective Laser Melting |

| Materials | Metallic powder |

| Max building size (X Y Z) | 70x70x40 mm |

| Min layer height | 20 microns |

| Max layer height | 50 microns |

3D Systems DMP ProX 200

Specifications

| Technology | Direct Metal Laser Sintering |

| Materials | Metallic powder |

| Max building size (X Y Z) | 140x140x125 mm |

| Min layer height | 10 microns |

| Max layer height | 50 microns |

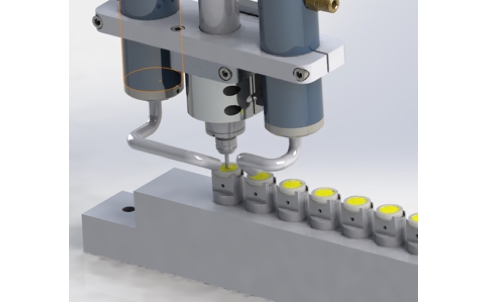

Cold Spray

Cold Spray (CS) is an innovative coating manufacturing process, which allows for the formation of material layers in a solid-state (free of melting) manner. STAM operates the only Cold Spray facility in Ireland, and is at the cutting edge of research and development of the process

In this method, the feedstock material (in the form of powder) is injected at the inlet of a converging-diverging supersonic nozzle. The nozzle is fed with high pressure gas (nitrogen or helium), which expands through the internal channel and reaches supersonic speed at the exit (above 1000m/s). Particles are dragged by the fast jet, and upon impact against a substrate material they plastically deform and stay bonded.

The density of the coating can be very high, combined with astonishing build rates to approach 250g/min. Also, the solid-state nature of the process allows for the preservation of feedstock properties/micro-structure and the elimination of Heat Affected Zones (HAZ).

Typical applications relate to wear resistance, corrosion protection and change of surface properties. Due to the bonding mechanism, not metallurgically compatible combinations are possible such as for the deposition of metals onto polymers and composites for aerospace, automotive and bioengineering applications.

STAM Cold Spray Facility

Specifications

| Technology | Cold Spray |

| Materials | Metallic powder |

| Maximum Pressure | 40 bar |

| Max Particle Velocity | > 1000 m/s |

| Max Gas Heater Temp | 1000 C |

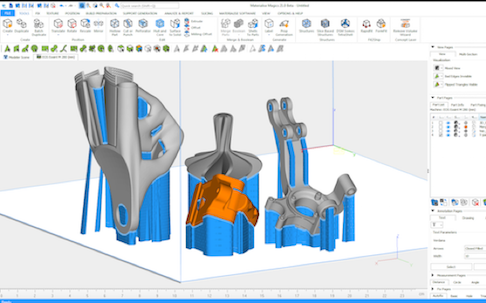

Design For Additive Manufacturing (DFAM)

Design for Additive Manufacturing (DFAM) is design for manufacturability as applied to additive manufacturing (AM). STAM uses a range of design methods and tools to fully explore and optimise functional performance and other key product life-cycle considerations such as manufacturability, reliability, and cost when manufacturable items are subjected to the capabilities of additive manufacturing technologies.

Technology

- Computer Aided Design Laboratory

- CAD Software: SolidWorks, Creo

- Finite Element Analysis: Ansys Workbench

- 3D Printing Software: Materialise

Polymer and Ceramic 3D Printers

Lithoz

Specifications

| Technology | Laser Lithography |

| Materials | Ceramics and Polymers |

| Resolution | 40 (x) 40 (y) 20 (z) nanometres |

| Build Volume | 73 (x) 43 (y) 150 (z) mm |

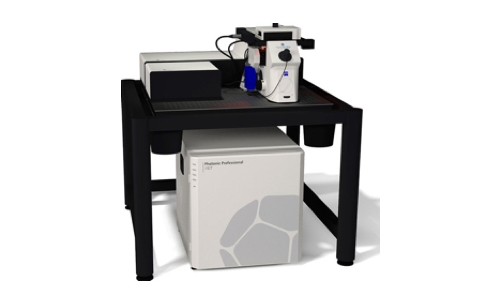

Nanoscribe Photonic Professional GT

Specifications

| Technology | Laser Lithography |

| Materials | Polymers |

| Resolution | 160 (x) 160 (y) 160 (z) nanometres |

| Build Volume | 10 (x) 10 (y) 10 (z) mm |

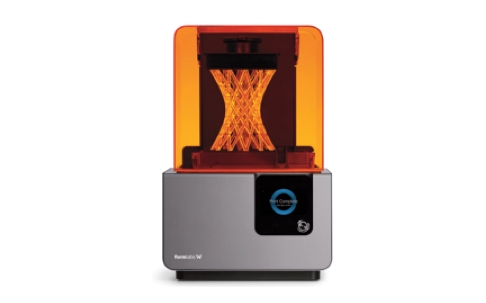

Formlabs Form 2

Specifications

| Technology | Stereolithography (SLA) |

| Materials | Polymers |

| Resolution | 140 (x) 140 (y) 25 (z) microns |

| Build Volume | 145 (x) 145 (y) 175 (z) mm |

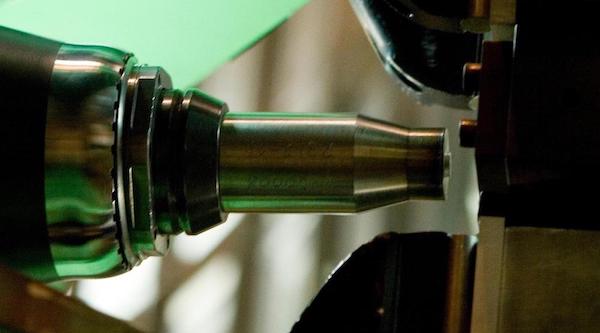

Machining & Joining

Aerotech Micro Milling Machine

Specifications

| Technology | Micro Milling |

| Materials | Polymers |

| Output Power | 100/150W |

| Precision | +/- 5 microns |

| Cooling System | Vortex Tubes |

Friction Stir Welding (FSW)

Specifications

| Technology | Friction Stir Welding |

| Materials | Aluminium, Steel, Polymers |

BRM 90130 Laser Cutting Machine

Specifications

| Technology | Laser cutting |

| Materials | Metal, wood, polymer, ceramics. |

| Output Power | 100/150W |

| Precision | +/- 0.1mm |

| Max Running Speed | 1000 mm/s |

| Max workpiece size | 900x1300x230 mm |

Testing and Process Monitoring Facilities

Measurements and Data Acquisition

We have a range of equipment for measuring forces such as cutting, axial, torque and deflective forces when drilling, threadcutting etc., enabling high resolution measurements of the smallest dynamic changes in large forces. We also have a suite of capacities with regards the development of tailored control & monitoring solutions for facilities, equipment condition monitoring, and manufacturing process applications.

Equipment

- Sensor systems:- Force dynamometer, Acoustic Emission, Vibration, Mass, Micro displacement, Thermal imaging, Machine vision, Pressure, Temperature, Gas Flow, Power, Voltage & Current

- Actuators:- Hydraulic, Pneumatic, Servo-motor, Stepper-motor and other precision rotary & linear actuators

- Software packages:- LabVIEW, Matlab, ANSYS, ProE, Solidworks etc.

- Data acquisition & control systems:- National Instruments PXI chassis with controller and range of NI PXI modules; NI Compact RIO chassis; NI Compact Daq chassis, and range of C-series modules for thermocouple I/P, analog and digital I/O, Serial communications etc.; various Omron PLCs & I/O modules

Mechanical Testing Equipment

We have a range of Instron and other equipment for evaluating material properties through Tensile (including up to 50 kN pull force), Compression, Fatigue and Hardness tests.

Equipment

- 3 Instron servo-hydraulic testing machines

- 3 Instron screw-driven tensile testing machines

- 1 MTS Tytron electromagnetic testing machine

- Hardness testing machines (macro, micro and nano)

- Charpy/Izod impact tester

Imaging Facilities

Access to The Advanced Microscopy Laboratory in CRANN

The CRANN Advanced Microscopy Labratory (AML) is a custom designed, 6,000 square foot facility, located in the Trinity Technology and Enterprise Campus.

The research equipment includes a Carl Zeiss Helium Ion Microscope [HIM], an FEI Titan Transmission Electron Microscope [TEM], and five other high specification scanning electron and focused ion beam microscopes. The Titan is the highest resolution TEM in Ireland and has powerful analytic capability. The HIM is one of only a handful in Europe, giving higher imaging resolution than a traditional scanning electron microscope, and is the only one located in Ireland.

- Zeiss Orion Plus — Helium Ion Microscope

- FEI Titan — Transmission Electron Microscope

- Zeiss Auriga — Focused Ion Beam (FIB) with Cobra ion column

- FEI Strata 235 — Focused Ion Beam

- Zeiss Ultra Plus — Scanning Electron Microscope

- Zeiss Electron Beam Lithography SEM — Supra 40

- Zeiss Electron Beam Lithography SEM — EVO 50

- Fischione NanoMill 1040

- Zeiss ORION Nanofab

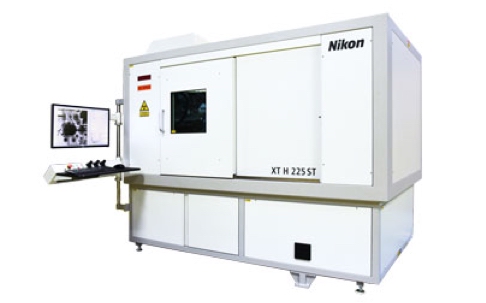

XT H 225 ST Industrial CT scanning (In collaboration with AMBER)

The XT H 225 ST is a Computed Tomography (CT) system ideally suited to a wide range of materials and sample sizes, especially those that are too large or heavy for other systems in the range. the system has three interchangeable sources; the 225 kV reflection target, 180 kV transmission target and the optional 225 kV rotating target.

Specifications

| Technology | Computed Tomography |

| Source | 225 kV microfocus X-ray source |

| Output Power | 100/150W |

| Precision | 3 micron focal spot size |

| Max Sample Weight | 50 kg |

| Max Sample Size | 50 cm diameter |

HotShot 1700 cc High Speed Camera

A ruggedized, compact highspeed camera system.

Specifications

| Technology | CMOS Sensor |

| Max. Frame Rate | 100,000 fps |

| Max. Resolution | 1696 by 1720 |

| Bit Depth | 10 bit |

Our Services

STAM has a long and established track record in applied research in manufacturing engineering and in engagement with the manufacturing industry in Ireland and internationally, through collaboration, design support and project delivery.

In particular, we have a suite of capacities with regards additive manufacturing, the development of tailored control & monitoring solutions for facilities, equipment condition monitoring, and manufacturing process applications.

Our flexible and collaborative approach delivers efficient, accurate, and robust products and results, as well as the tools to leverage test data for effective results analysis.

We are comfortable developing custom turnkey systems or working alongside your company’s R&D team to deliver your vision.

Additive Manufacturing Services

Manufacturing Process Analytics

We can develop systems using a variety of software and hardware platforms (custom and off-the-shelf), data acquisition systems, and control methods. Over the last number of years, we have been using the LabVIEWTM software development system in both teaching & research. Our researchers and technical staff have experience and expertise in the development of data acquisition, logging, visualisation and the implementation of machine interface and control using this development platform.