Wi-FORCE - Wireless Passive Force Measurement in Machining

Project Coordinator

Dr. Garret O'Donnell

Garret.ODonnell@tcd.ie

+353 1 896 1184

Dr. Sean Nolan

snolan1@tcd.ie

Description

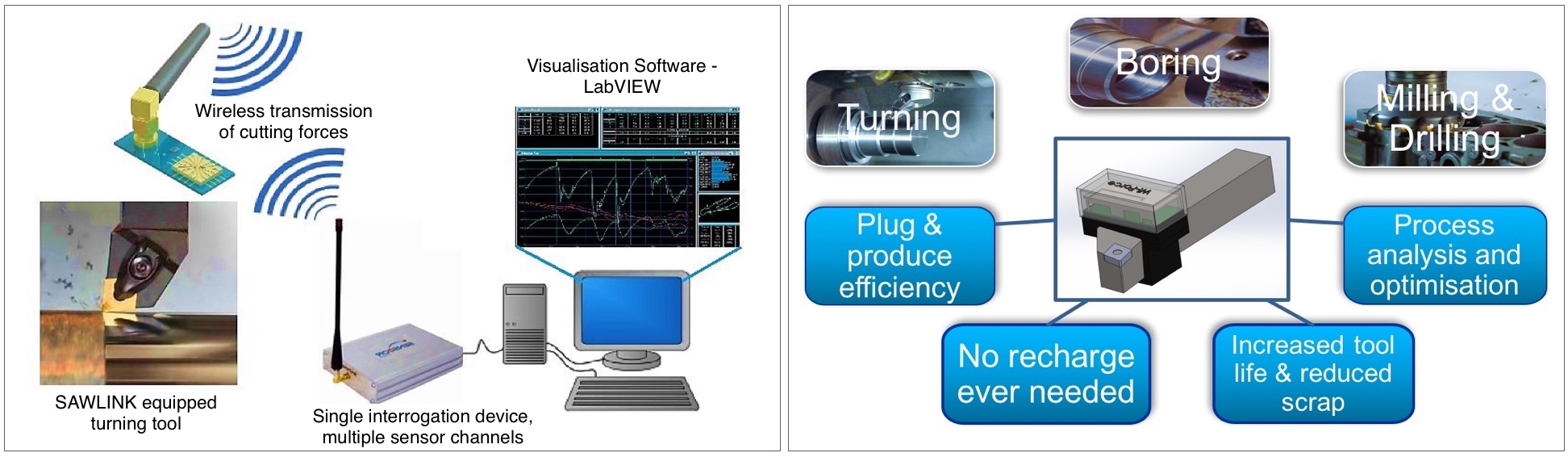

Wi-FORCE enables wireless passive tool force measurement during high-tech biomedical, automotive and aerospace machining applications facilitating online process optimisation and monitoring. Benefits are:

- Real-time monitoring of cutting forces

- Cost and scrap reduction due to optimisation of tool life and manufacturing processes

- Wireless, passive, and minimally invasive setup allowing better proximity to the cutting process

- Plug and produce functionality.

High end industrial sectors such as medical device or aerospace manufacturing in high wage economies must be constantly pushing the technology frontiers in order to optimise their internal production processes and stay ahead of competition. Medical and aerospace manufacturing companies have metal cutting at the core of their production processes and technologies such as Wi-Force that allow for optimisation of these processes directly impact on the core of these companies value adding activity.

Wi-FORCE Setup Overview, Applications and Benefits

The Wi-Force project is developing a cost effective non-invasive wireless passive rotary tool force measurement solution that provides process information that can be used to:

- Monitor wear during cutting therefore reduce tool replacement costs

- Detect chatter and detection/prediction of tool breakage therefore eliminating scrap

- Enable data driven parameter optimisation therefore improve quality and productivity

- Enable automated process supervision therefore reducing manning of machine tools

Crucial to the success of the project is the need for a product that meets the requirement for the seamless ability to substitute an instrumented tool holder for a standard tool holder in order to achieve acceptability. Wi-Force is unique in this regard as a plug and produce technology.

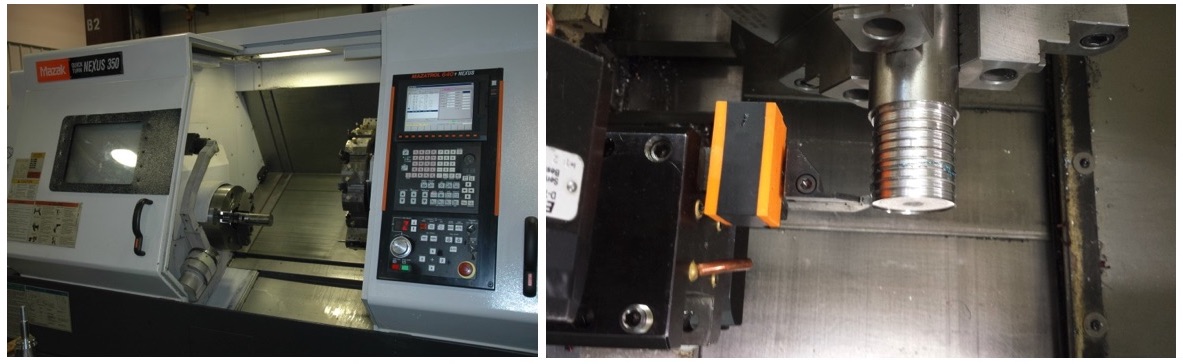

The machine-tool add-on SAWLINK is a wireless, passive force sensor for tool condition monitoring. During machining operations, it can measure the force and strain induced in the tool and holder. The data is transmitted wirelessly to the SAW interrogator and can be subsequently used to optimise the machining process, ensuring quality and productivity.