Professor Matthew John M. Krane, Associate Professor of Materials Engineering, Purdue University will give a seminar on

Computer modelling of flow and segregation defect formation in remelting processing of high temperature alloys

Tuesday 13 May 2014, 12pm, Crossland Lecture Theatre, Parsons Building

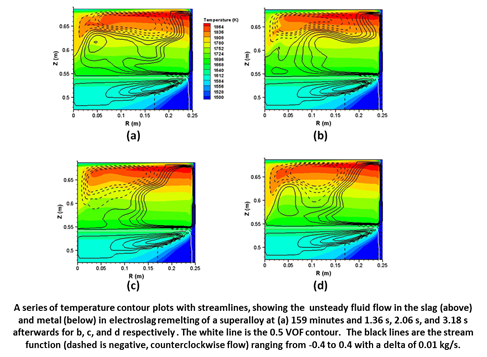

Remelting processes provide routes to large ingots of specialty metals which have relatively few defects. However, past certain limits on size of the ingots and speed of these processes, several types of segregation related defects begin to occur. The heat, mass and momentum transfer and electromagnetics present during electroslag and vacuum arc remelting (ESR and VAR) are modelled and sump profiles and macrosegregation patterns are predicted. These results are studied as functions of process parameters and ingot geometry. During ESR of nickel-based superalloys, freezing and remelting of a slag skin between the ingot and mold changes the thermal response of the ingot. Changes in process current and alloy composition are also examined to reduce segregation. During VAR of titanium alloys, DC current levels are generally much higher than the AC current in ESR, so the sump flow is controlled by Lorentz forces, leading to different segregation patterns. The numerical simulations include studies of two distinctive flow regimes in VAR: strong counter-clockwise Lorentz driven flow and weak clockwise buoyancy driven flow. The results demonstrate the influence of flow regime on macrosegregation patterns and microstructural distribution.

Dr. Matthew Krane is an Associate Professor of Materials Engineering at Purdue University and a member of the Purdue Center for Metal Casting Research. His research is on design, development, and modeling of materials processes, particularly the solidification of metal alloys. Research projects include numerical process modeling of VAR, ESR, and DC casting, looking at the effects of transport phenomena on the formation and prevention of solidification defects. He is part of a team working on the through- process modeling of aluminum production, from direct chill casting through homogenization to extrusion. Other projects examine the investment casting of superalloy parts with thin sections, the microstructural modeling of dendritic growth, and the prediction of fluid flow in high pressure die casting.

Prof. Krane holds a Ph.D. (1996) from Purdue University in Mechanical Engineering, with a concentration in heat transfer and fluid flow in materials processing. His M.S. (1989) is from the University of Pennsylvania and his B.S. (1986) from Cornell University, both in mechanical engineering. In addition to consulting with the metals processing industry, he also worked for three years (1988-1991) on thermal packaging and manufacturing issues for Digital Equipment Corporation in Andover, Massachusetts. In 2006, he was a Visiting Research Fellow working in the Interdisciplinary Research Centre at the University of Birmingham (UK) and was granted a courtesy appointment in Purdue’s School of Mechanical Engineering in 2008. He has chaired the TMS Process Modeling and Control and Solidification Committees, and co-chaired Modeling of Casting, Welding and Advanced Solidification Processes (MCWASP X) in 2003 and the Liquid Metal Processing and Casting (LMPC) Conferences in Nancy (2011), Austin (2013), and Leoben (2015). Professor Krane’s teaching experience includes heat transfer, fluid mechanics, process design, materials processing, numerical modeling, and ethics in engineering practice.

Organised by Dr Shaun McFadden, Assistant Professor in the Department of Mechanical and Manufacturing Engineering, shaun.mcfadden@tcd.ie.