TOSCA

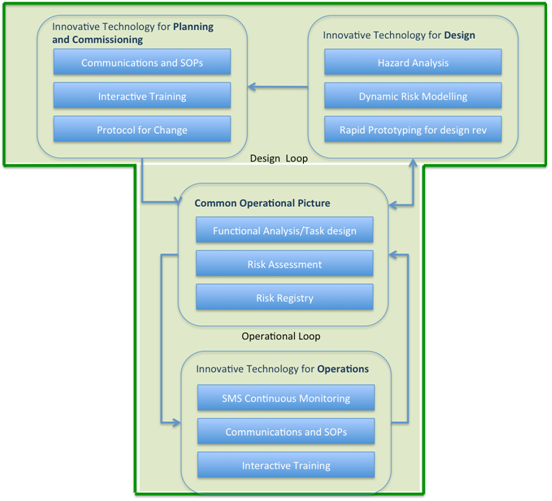

TOSCA (Total Operations Management for Safety Critical Activities) is concerned with the integration of industrial operations into a total performance management system. Within TOSCA safety, quality and productivity are addressed in an integrated way during the lifecycle of projects or products. TOSCA's industrial domain of application concerns process control industries (e.g., chemical industries, power generation, offshore oil & gas platforms, etc.) that may vary in size, regulatory and cultural aspects. TOSCA will examine vulnerabilities of the technical, human and organizational systems that may have an impact in safety, quality and productivity. Safety of critical activities can be seen as ‘projects' or ‘safety cases' that must be examined from the perspectives of many stakeholders (e.g., different departments, subcontractors, regulatory authorities, etc) and decision-making at different organizational levels (e.g., top managers, supervisors and operators). A participative approach is required that will collect knowledge from the sharp-end operators and integrate it with formal descriptions of system operation and response. Furthermore, TOSCA will enhance the management of change and provide an environment for testing out the effectiveness of possible action plans.

The objective of TOSCA is to deliver a "ready to apply" integrated methodology that comprises a modeling approach, an integrated set of methods and supporting IT tools for total performance management in all phases of design, operation, maintenance activities that are carried out by plant personnel or subcontractors. This will be done in accordance with ISO 31000 and will be transferable across different domains and organizational sizes.

Specifically TOSCA will:

Deliver a methodology and a set of toolsets to manage safety-critical activities through the phases of Operations, Safety and Quality Management; in this way, safety, quality and productivity will be integrated into a total performance management system.

Incorporate innovative "knowledge management" methodologies to generate, store and update risk-related data from various sources (e.g., plant procedures and drawings, safety warnings, near miss reports, operator practices on the job, and authority requirements). In this sense, knowledge from safety practitioners and operators will be integrated with formal knowledge of how a target system works.

Incorporate advanced concepts and techniques for modelling the role of human and organizational factors in risk analysis with emphasis on resilience and capabilities for timely detection, communication, reporting and recovery of variations and disruptions.

Utilise emerging technologies to enhance the gathering, modelling and management of risk-relevant data (e.g., virtual and augmented reality, computer aided design, information systems and enterprise resource planning). This will provide a test bed facility for ‘experimental risk analysis' as well as ‘change management' (e.g., testing the effectiveness of risk reduction measures).

Provide facilities for learning and updating the risk reduction tools to enable adaptation to new changes in the organizational environment. This is related to several aspects of organizational learning and interactive design of systems.

PI

Sam Cromie, Maria Chiara Leva

Timescale

February 2012 - February 2016

Funding provider

EU-FP7